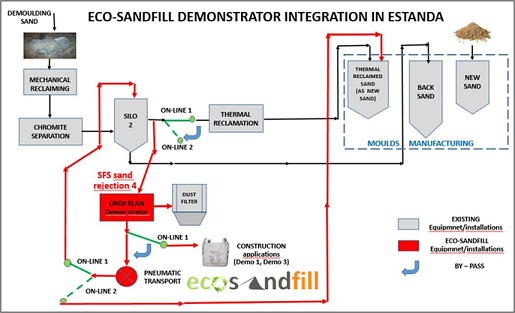

Action B1. Integration of the sand reclaiming process in the factory

Based on the analysis of the results of the adjustments tests carried out on a demo equipment at ONDARLAN, the design of the components of the custom-built prototype has been made, to yield sand of the specified quality considering the characteristics of the input SFS from ESTANDA.

The analysis for the integration of the customer-built prototype has included:

- Selection of the adequate sand rejection flow in ESTANDA’s sand treatment circuits to be used as input SFS to the reclaiming prototype.

- Analysis of the storage capacities for the total SFS and reclaimed sand: volume of the silos and hoppers existing at ESTANDA.

- Material conveying and handling systems for the SFS and reclaimed sand flows to and from the prototype: pneumatic transport, conveyor belts, other auxiliary equipment.

- Prototype location: available spaces, flow of the sand reclaiming process (control and automation of the reclaiming process equipment and components), collision or disruption with other foundry processes.

- Evaluation of available infrastructures and services: electricity supply, compressed air, safety defences.

- Other additional aspects to be considered: productivity and operational costs, preventive maintenance plan, safety and hygiene conditions at work, management of equipment purchases, physical assembly and coordination of working tasks.

The final arrangement consists of the effective integration of the prototype into the sand treatment facilities of the chemical moulding section of the foundry, with two alternative operation modes of the circuit. The assembly works are currently in progress (scheduled end date: Sep’2017).