Action A1. Adjustment of the reclaiming process to the use of the foundry sand in construction application

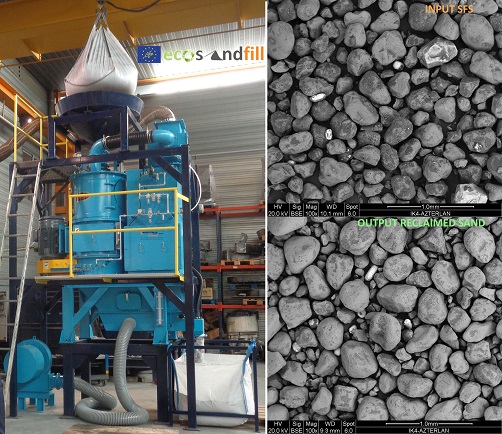

Design of Experiments techniques have been used to choose 20 combinations of process variables at different levels to run a series of experiments aimed at adjusting the process to the characteristics of the SFS generated by ESTANDA and achieving the final quality required for the foundry and construction applications. Those preliminary reclamation trials were carried out on a demonstrator located on the premises of ONDARLAN. The sand was supplied by ESTANDA and originated from its chemical and green sand moulding processes. The characterisation of input and output samples by ONDARLAN and IK4-AZTERLAN has allowed to optimise the equipment operation conditions, with a view to designing the prototype to be later integrated in the moulding sand circuit at ESTANDA facilities.

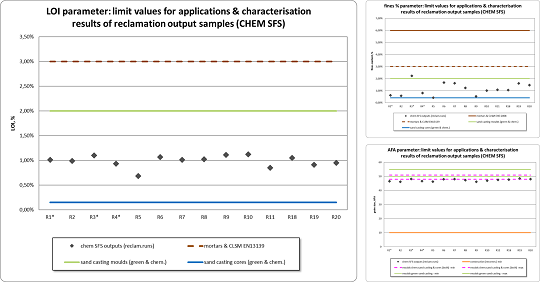

ESTANDA (as user of reclaimed sands in moulding systems at foundry) and ACCIONA (user of reclaimed SFS as substitute of natural sand in construction applications) have defined the physical-chemical specifications for each of the envisaged applications:

Output samples taken from every reclamation trial have been analysed and the values of the set of parameters used as cut-off criteria have been checked against the values specified for each application. All the samples of reclaimed chemical SFS meet cut-off specs for the envisaged construction applications and mould manufacturing in foundry, with reclamation yields >95%.

These results have been taken into account in ONDARLAN designs for building the custom-made reclaimer prototype to be attached to ESTANDA installations (B1 sub-Action) and for selecting the optimal levels of the operation variables to run on industrial conditions.